Cold Storage

Home // Cold Storage

Complete PUFF panel-based cold rooms for vegetables, fruits, dairy, and pharma

Turnkey cold storage construction with insulation & door systems

- Complete turnkey cold storage setup

- Insulated walls, ceiling, and floor using high-density PUFF panels

- Seamless integration of doors, refrigeration systems, and lighting

- Hygienic interiors with anti-bacterial surfaces

- Custom temperature range (-40°C to +10°C)

- Excellent thermal insulation reduces energy bills

- Faster construction & installation time

- Complies with FSSAI & pharma-grade standards

- Low maintenance & long-lasting durability

Frigowall

Frigowall is the most suited insulated sandwich panel for cold storage industry due to its “stateof-the-art” double tongue and groove joint, which eliminates the risk of thermal bridge and avoids any moisture ingression between the panels. Frigowall is used for walls, partition and ceiling of the cold storage.

Double Tongue & Groove Joint

Double tongue and groove joint between the panels ensure precise inter locking and provide dimensional accuracy. The panels ae locked together by means of press fit and it has been designed in such a way that there are no thermal bridges and only foam comes in contact at the core of the panels.

Material Specifications

Monowall

Self-supporting metal panels insulated with polyurethane foam for use in refrigerated rooms with positive temperatures, industrial, commercial buildings and partitions in general. Monowall has single tongue and groove joint and it is used for walls, partitions and ceiling.

Single Tongue And Groove Joint

Single tongue and groove joints ensure the interlocking between the panels. The panels are locked together by means of press fit and it has been designed in such a way that there are no thermal bridges and only foam comes in contact at the core of the panels.

Material Specifications

Glamet

Self-supporting metal panel, insulated with polyurethane, for pitched roofs with a minimum slope of 7% used in industrial and commercial buildings and refrigerated warehouses. Glamet has over lapping joint and are used for roofing & wall cladding.

Over Lapping Joint

Over lapping joint ensures the interlocking between the panels. It arrests seepage and also gives additional strength to the panel to withstand all weather conditions and make it walkable.

Glamet is in the thickness of 30, 40, 50, 60, 80 & 100mm. All panels are with the cover width of 1000 mm.

Material Specifications

Table Of Safe Spans

Values guaranteed with steel sheets, thickness 0.6 + 0.5 mm. Spans l in metres, as a function of a uniformly distributed load p (daN/m2), have been obtained from experimental data and calculated to provide a deflection limit: f<=l /200 of the span and a minimum safety .

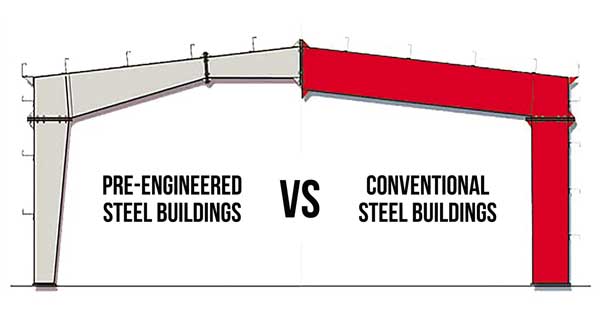

Industrial – Peb & Conventional

Pre-fab Shelters