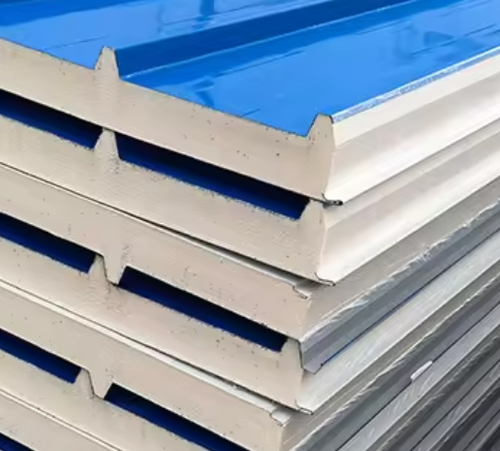

Puff Panel

Home // Puff Panel

State-of-the-Art Puff Panels

- CFC free and hence environmentally friendly

- High thermal efficiency /controlled temperature

- Non-corrosive hygiene surface

- Flexibility in size to suite requirements

- Well-bounded lamination

- Good dimensional stability

- Floor loads as per customers specifications

- High speed wind resistant

Energy Efficiency – Minimizes temperature fluctuations, reducing energy consumption and operational costs.

Product Quality – Maintains consistent temperatures to prevent spoilage, ensuring freshness and safety of stored goods.

Regulatory Compliance – Designed to meet industry standards for temperature control and hygiene.

Enhanced Productivity – Smooth and reliable operation minimizes downtime during loading and unloading.

Long-Lasting Durability – Built with high-quality materials to withstand harsh conditions, ensuring long-term performance and reliability.

| Characteristic | Value |

|---|---|

| Temperature Range | 80 to -50 °C |

| Density | 40 ±2 Kg/m³ |

| Compressive Strength | 2.1 Kg/cm² |

| Adhesion Strength | 3 Kg/cm² |

| Tensile Strength | 4 Kg/cm² |

| Thermal Conductivity | 0.02 W/MK |

|

Thickness (mm) |

60 |

80 |

100 |

120 |

150 |

|---|---|---|---|---|---|

|

‘U’ value (w/m2k) |

0.36 |

0.26 |

0.21 |

0.19 |

0.14 |

|

Properties |

Polyurethane |

Polyisocyanurate |

|---|---|---|

|

Density |

40+/-2kg/cu.m |

45+/-2kg/cu.m |

|

Compressive Strength @10% deformation |

2.1 Kg/cm2 |

2.1 Kg/cm2 |

|

Tensile Strength |

2.5 Kg/cm2 |

2.5 Kg/cm2 |

|

Bending Strength |

3.0 Kg/cm2 |

3.0 Kg/cm2 |

|

Close Cell Content |

90-95% |

90-95% |

|

Water Absorption |

0.2% volume at 100% RH |

0.2% volume at 100% RH |

|

Shear Strength |

2.5 Kg/cm2 |

2.5 Kg/cm2 |

|

Insulation |

CFC & HCFC Free rigid PUF as per is 12436 Standard |

CFC & HCFC Free rigid PIR as per is 12436 Standard |

Technical Specifications of Sandwich PUF/PIR Panels

| Skin Material Options | |

|---|---|

|

|

| Specification | Details |

| Skin Material & Thickness Options | 0.35mm, 0.40mm, 0.45mm, 0.50mm, 0.60mm with Polyester Paint on Chromate Treatment |

| PUF Density | 40 Kg/m³ +/- 2 Kg/m² |

| Thermal Conductivity (K Value) | 0.02 to 0.03 W/m-K |

| Closed Cell Content | 93% +/- 2% |

| Water Absorption | Below 0.2% at 98% RH |

| PUF Adhesion Strength | 2.9 Kg/cm² |

| Compression Strength | 2.1 Kg/cm² at 10% deformation |

| Dimensional Stability | Above 99% |

| Eco-Friendly | Yes (100% CFC Free) |

| Fire Resistance | Class B, C (PUF), Class A (PIR) |

| Type of Panel Joint | Tongue and Groove, with Camlock |

Panel Thickness & Temperature Range

| Panel Thickness (mm) | 60 | 80 | 100 | 120 | 150 | 200 |

|---|---|---|---|---|---|---|

| Temperature Range (°C) | +5 to +20 | +2 to -8 | -8 to -18 | -15 to -25 | -25 to -40 | -40 to -50 |